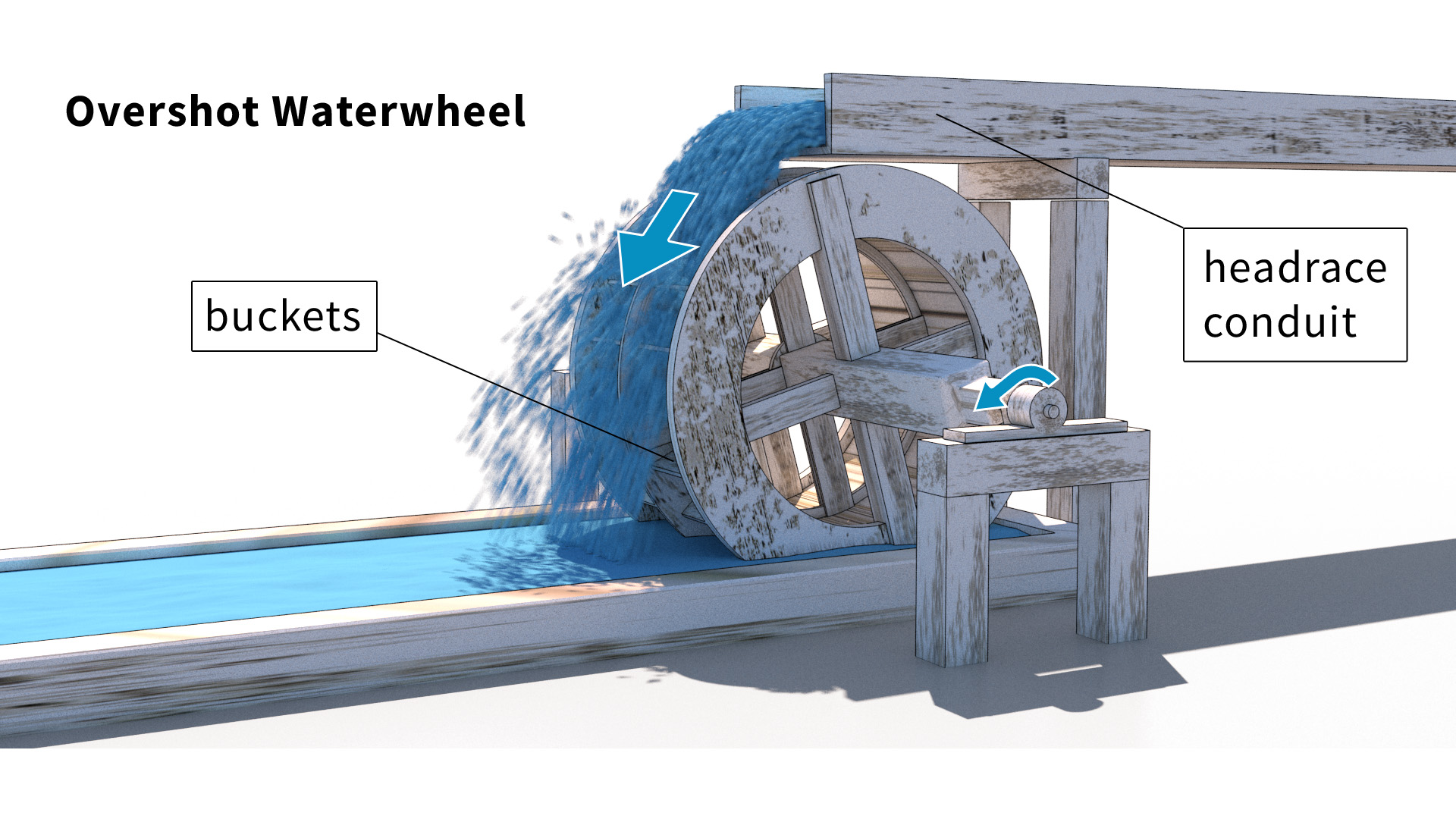

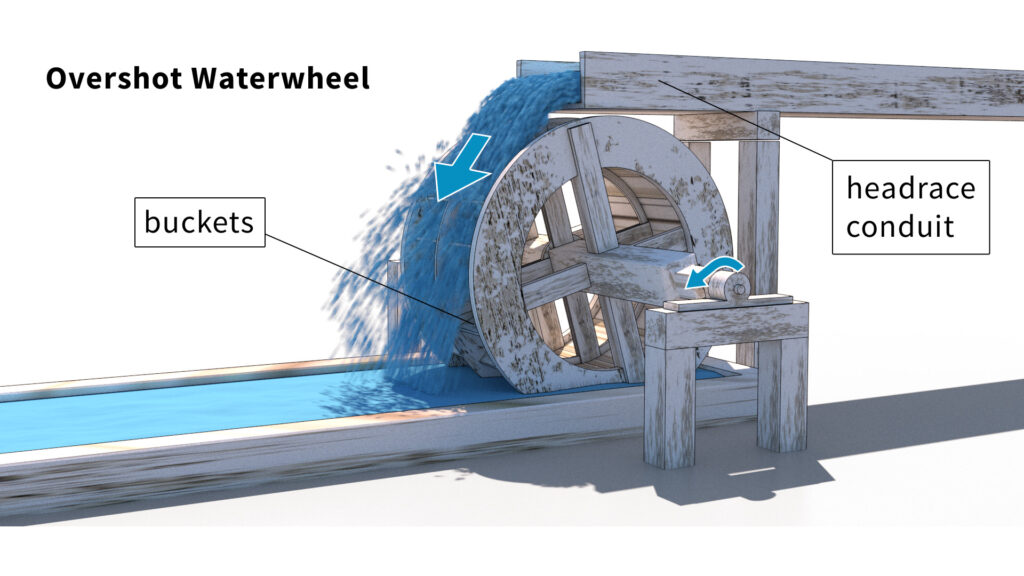

A channel or pipe located above the waterwheel directs the water onto the blades from above. The waterwheel has closed blades, so-called buckets. When the water fills the buckets, the wheel is set in motion by the weight of the water. The head of an overshot waterwheel is usually between three and 10 metres.

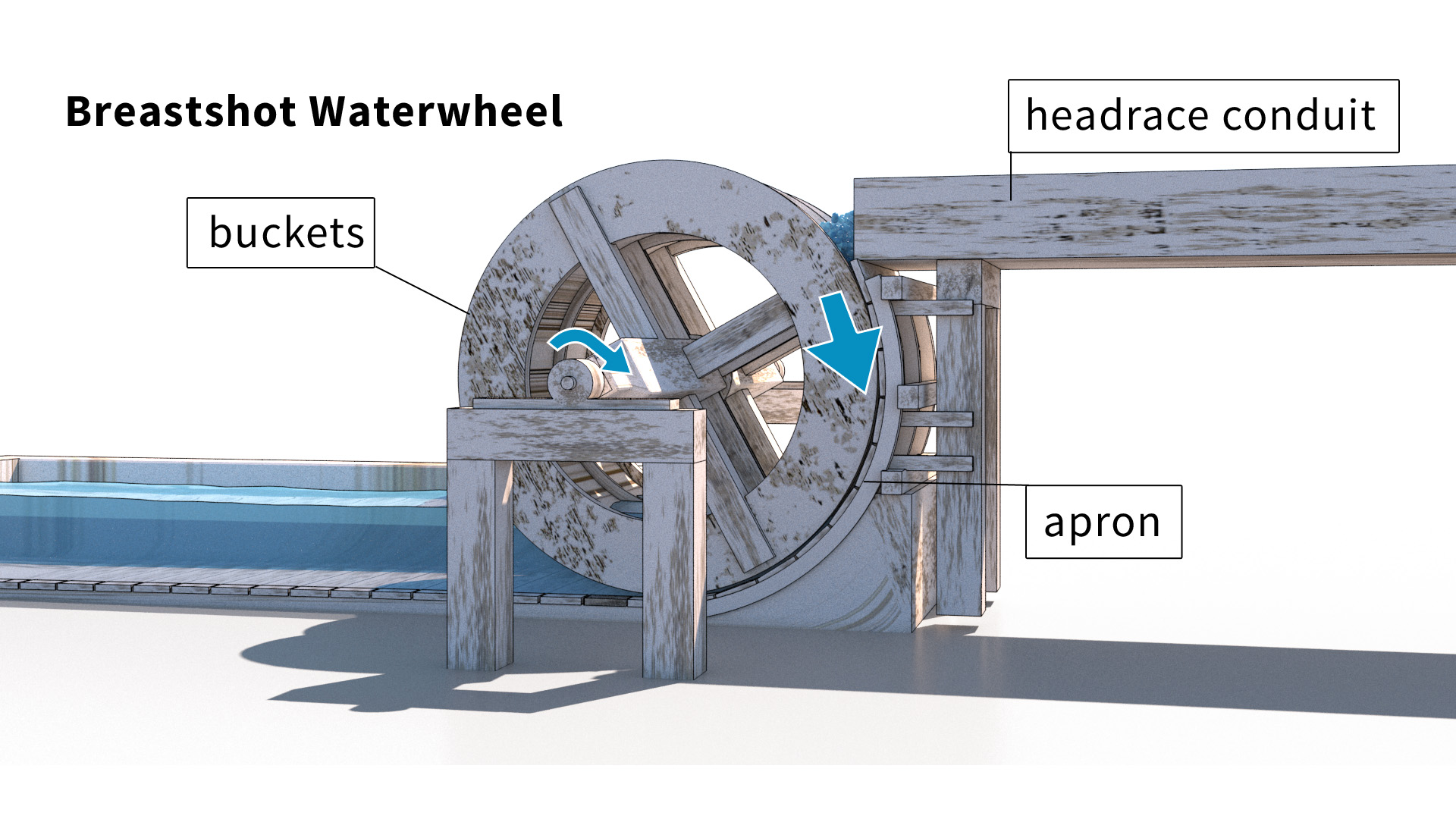

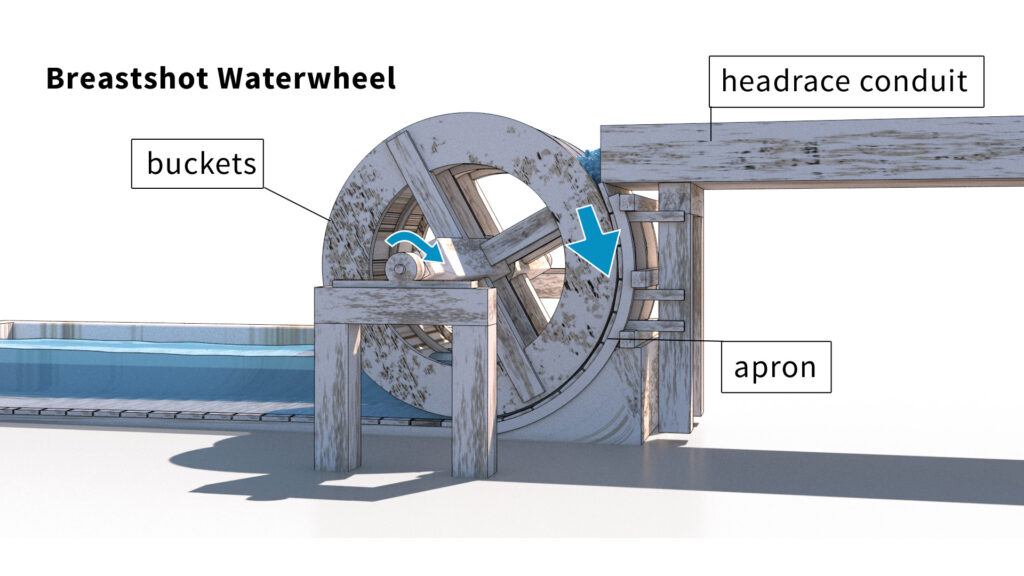

The water is fed to the waterwheel through a conduit or directly via a sluice gate – usually at hub height or slightly above. There is an apron closely conforming to the curvature of the waterwheel to prevent the loss of water. The breastshot waterwheel can be fitted with closed buckets or with blades. In order to compensate for the lower difference in height and the lower gradient of the inflowing water, breastshot waterwheels are built broad and massive. In the case of the breastshot waterwheel, both the weight of the water and the momentum – the current – are effective.

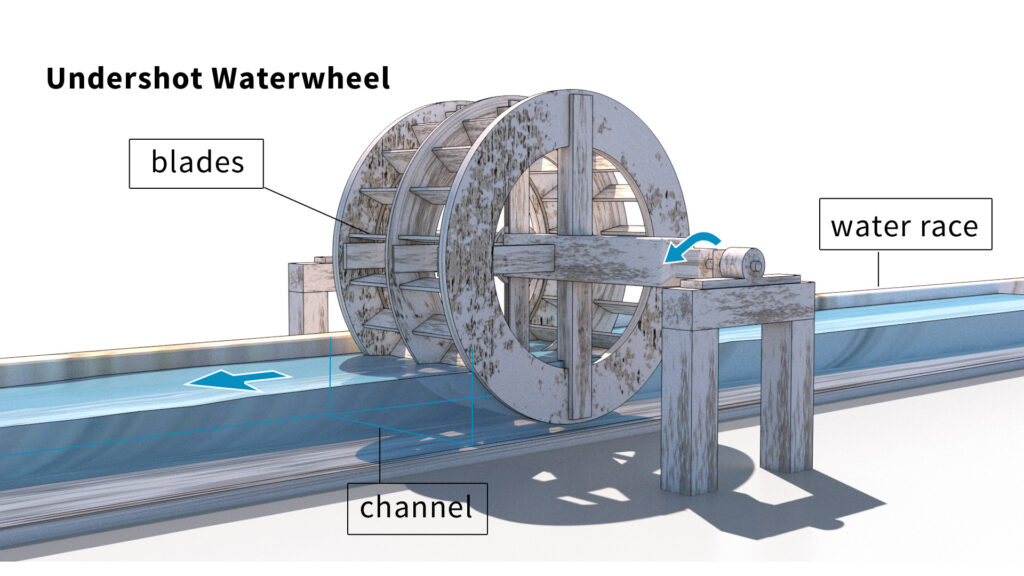

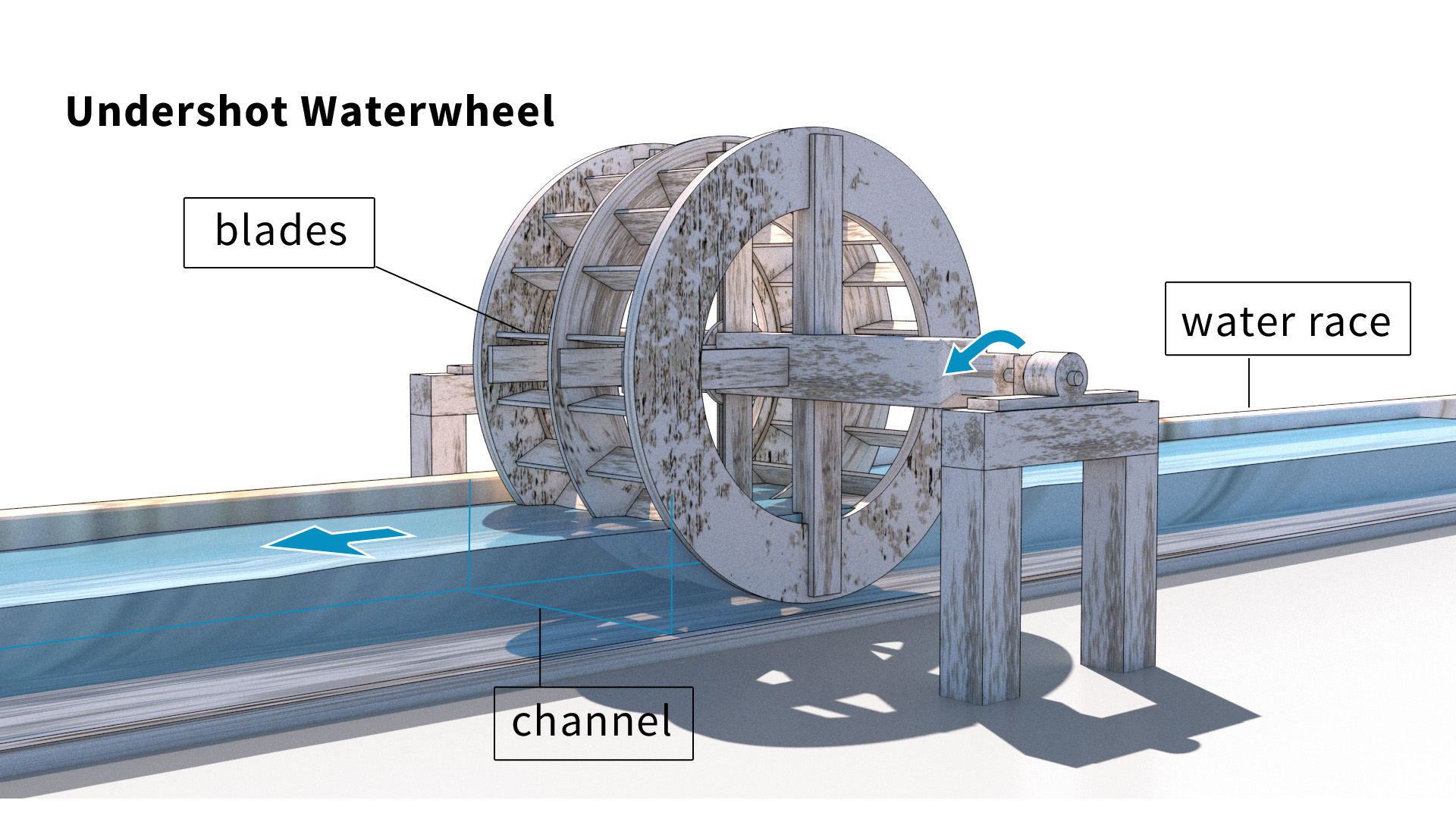

In the case of undershot waterwheels, the water flows under the wheel in a duct (channel). The duct is made to fit the wheel. It ensures that the water cannot flow underneath or past the sides of the waterwheel without driving it. Undershot waterwheels are the oldest known type of waterwheel. The power transmission occurs via blades. At their simplest, the blades consist of a wooden board, but greater efficiencies are achieved with specially curved sheet metal blades.